The public, regulators and investors require solid actions to minimize the greenhouse gas (GHG) emissions of materials and services due to the climate change risks. Thus, the mining sector is seeking alternatives to reduce its carbon footprint. However, integrating new technologies takes time and requires analysis of the operational trade-offs and risks due to the capital intensity and technical and business risks.

The current trends in the decarbonization process direct the miners mostly towards “electrify all” practices with battery-electric and trolley-assist trucks, on-site renewable energy projects, as well as green hydrogen applications. However, the unique characteristics of operations, including life-of-mine, operational jurisdictions, and production and process requirements, are major factors for miners that must be considered before taking the “electrify all” path.

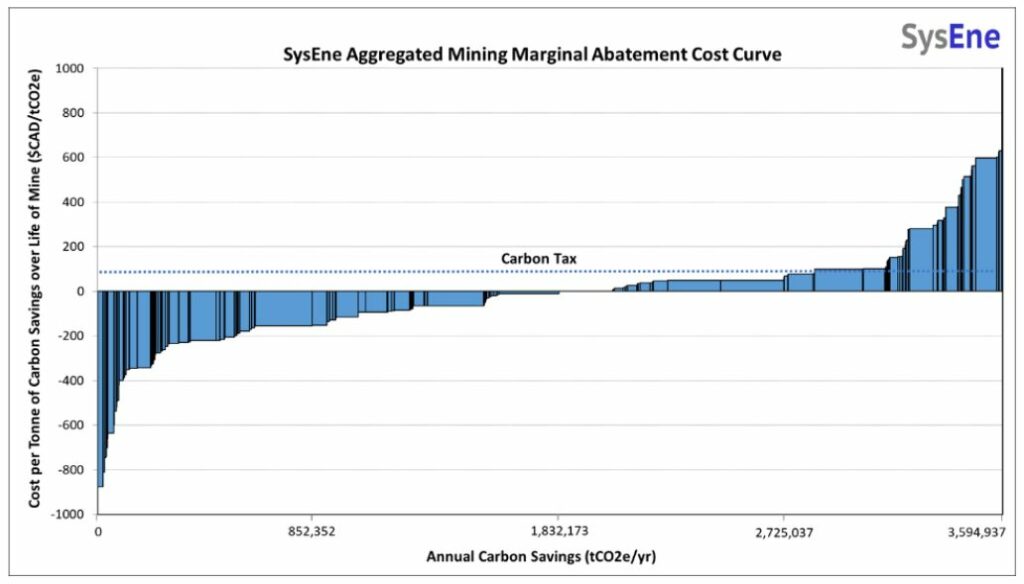

The popular, innovative electrification technologies are also proposed to be integrated into the business-as-usual design, planning and operational mindsets. Hence, the majority of current decarbonization work misses significant reduction opportunities with lower costs and risks due to the business-as-usual-based “electrify all” tunnel vision. SysEne has been working on the decarbonization roadmap projects of over 100 mining operations owned by over 20 mining companies. The aggregated marginal abatement cost curve for decarbonization in Figure 1 indicates that approximately 30% of the GHG reduction can come from low-cost and risk mitigation measures, such as operational energy efficiency and electrification of stationary and mobile auxiliary equipment.

Figure 1. The aggregated marginal abatement cost curve for various decarbonization measures in mining.

Therefore, at SysEne, we analyze mining systems holistically and determine the decarbonization alternatives for mining companies by considering the carbon emissions reduction potential, current and future affordability, maturity, and at-scale applicability criteria before performing detailed studies and making suggestions.

Efficiency and lower emissions factors are two criteria that affect carbon reduction potential, and our studies show inconsistent decarbonization potential for miners based on the current electricity infrastructure where they operate. Thus, depending on the clean electricity accessibility limitation, equipment electrification may not be the most promising decarbonization option. In addition to the decarbonization potential, affordability, and current maturity criteria, some of the electrification and green hydrogen-based options become marginal to uneconomical for many mining operations.

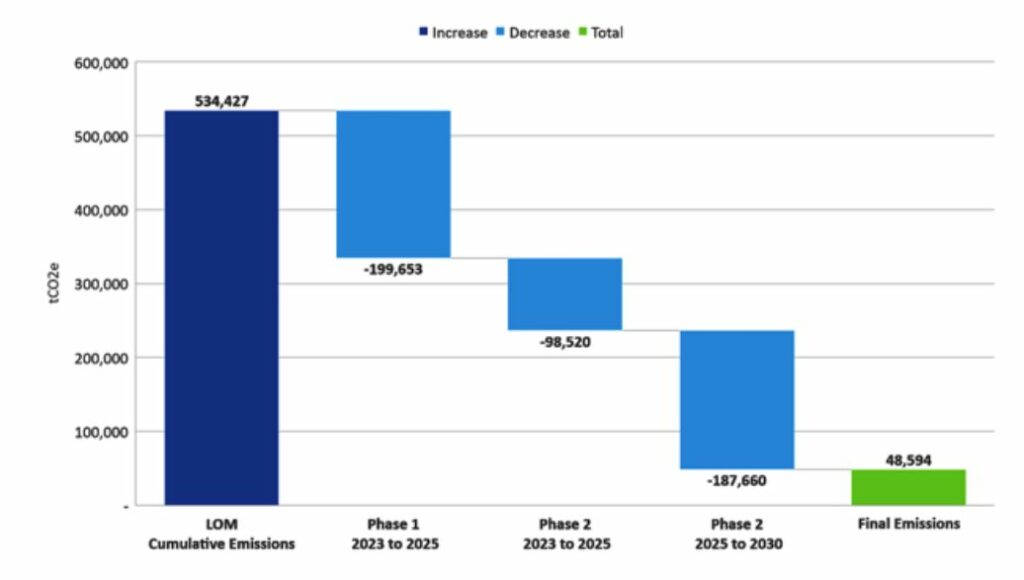

In addition to the holistic system-based approach, SysEne also considers alternatives to eliminate the barriers that come with business-as-usual culture in mining. Our studies show that early engagement and consideration of alternatives, as early as the pre-feasibility stage or expansion studies, give high flexibility to decarbonize mine sites with relatively low costs. Figure 2 summarizes the decarbonization plan for a surface mine at the late feasibility stage in a clean electricity and high grid connectivity jurisdiction.

Figure 2. Life-of-mine emissions reduction plan of a mine.

The advantage of early consideration of alternatives is that our clients can evaluate the specific equipment and technology without pre-defined limitations and use the decarbonization potential and low-energy requirement aspects as decision parameters. These help them shape the operational, processing, sustainability and health and safety policy and programs accordingly.

Contact us for further information and how SysEne’s experienced technical team may help you decarbonize your operations.

Dr. E. Deniz Yaylaci

SysEne Consulting Inc.

Related Insights

Check out some of the other tech innovation taking place in

the public transit space.